Thermal Heat Shielding

What is it and what can it do?

In the pursuit of technology and performance in most modern and performance engines, heat control becomes a challenging factor. Uncontrolled engine heat can cause major damage to the engine and engine components as well as increasing the air intake temperatures which will hinder the engine’s performance potential.

Turbo chargers, exhaust manifolds and downpipes are contributors of extreme temperatures of up to 1000°C. Any surrounding components are exposed to these kinds of temperatures which can be harmful.

The thermal heat shielding process found in Formula 1 racing, Aerospace and even in modern engines of today, is a technology developed to control heat to maximise performance and protect the engine and connecting components.

Advantages

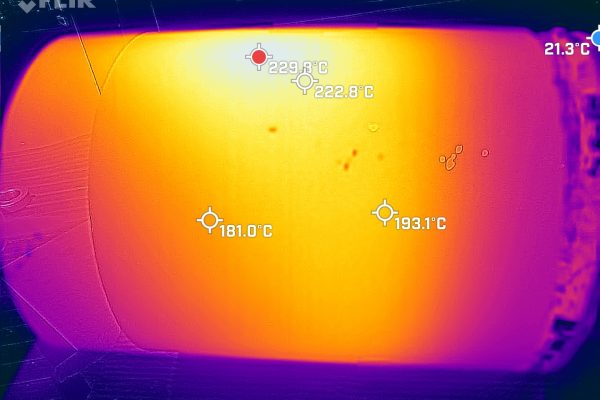

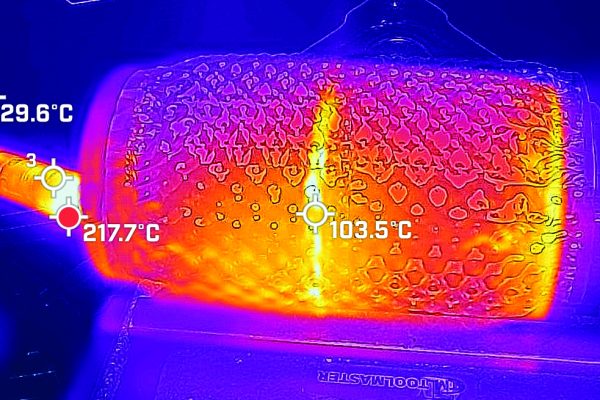

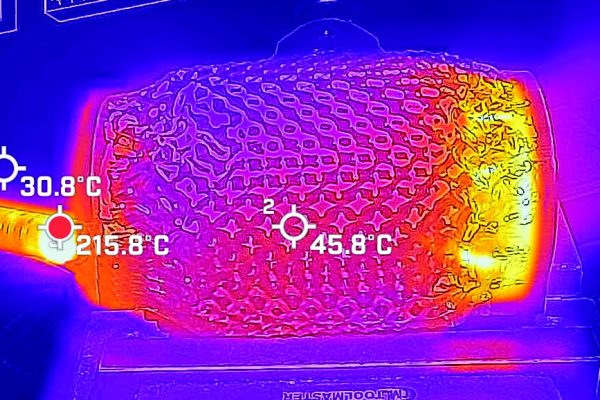

This heat shielding process keeps the heat inside the shielded component which helps with faster heat flow and reduces the surface temperature of the exhaust systems and turbo components thereby maximising thermal efficiency.

It protects the engine components surrounding these high heat expelling items. With the increase of plastic and rubber components in modern day vehicles this is significant in prolonging the life of components.

Another benefit is the reduced risk of fire in the event of any fluid spillage within the vehicle. Heat shielding insulation, unlike conventional heat protection tapes or covers, does not soak up oil and fuel and encapsulates the component thereby not allowing fluids to collect on the heated surface below the shielding.

A reduction in expelled heat from the heat shielded components allows reduced engine bay temperatures which lowers air intake temperatures and reduces heat soak. Lower temperatures boost engine performance without any more demand from your engine.

Services

Typical application examples are downpipes, turbo housings, wastegates and manifolds.

Each vehicle component is unique and we take pride in working meticulously to achieve the most thermal efficient and aesthetically pleasing result.

Thermal heat shielding is applied by encapsulating the component with a microthermal underlayer and a thin embossed metal sheet layer. These are affixed and sealed using a specialised welding process which ensures the shielding does not come loose.

We offer stainless steel shielding as well as titanium shielding for titanium components.

Contact Us

Its important to send us an image of your parts when requesting a quote especially if the parts are custom made. Each part is unique to its vehicle and quoted prices depend on the sizes and complexity of the parts.

Complete the below form to send an email or contact us via